Building the Fraser River Tunnel

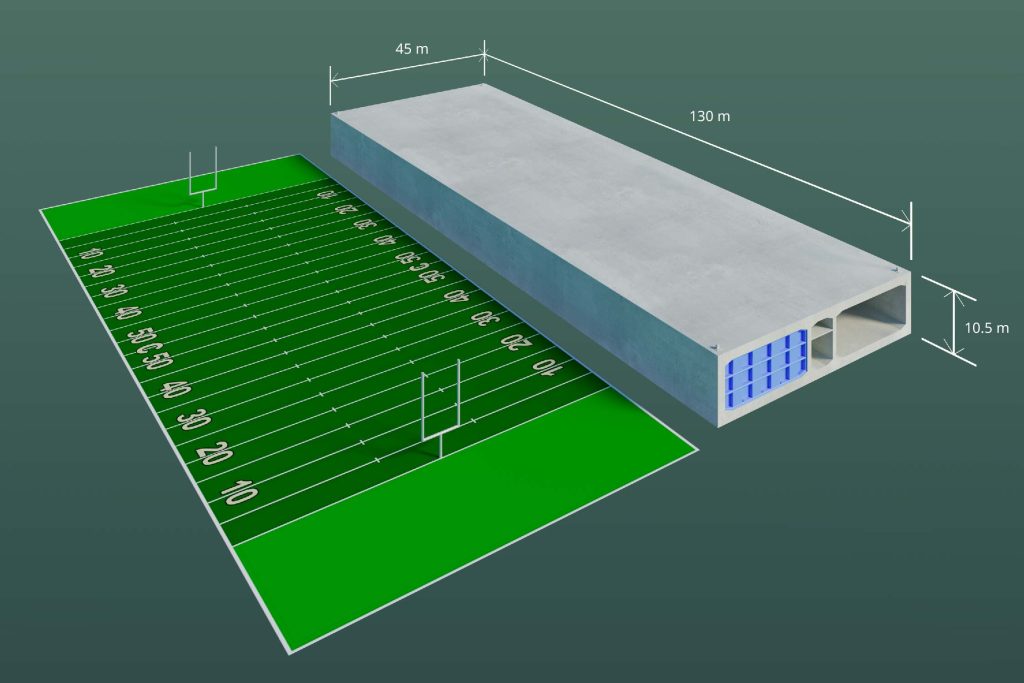

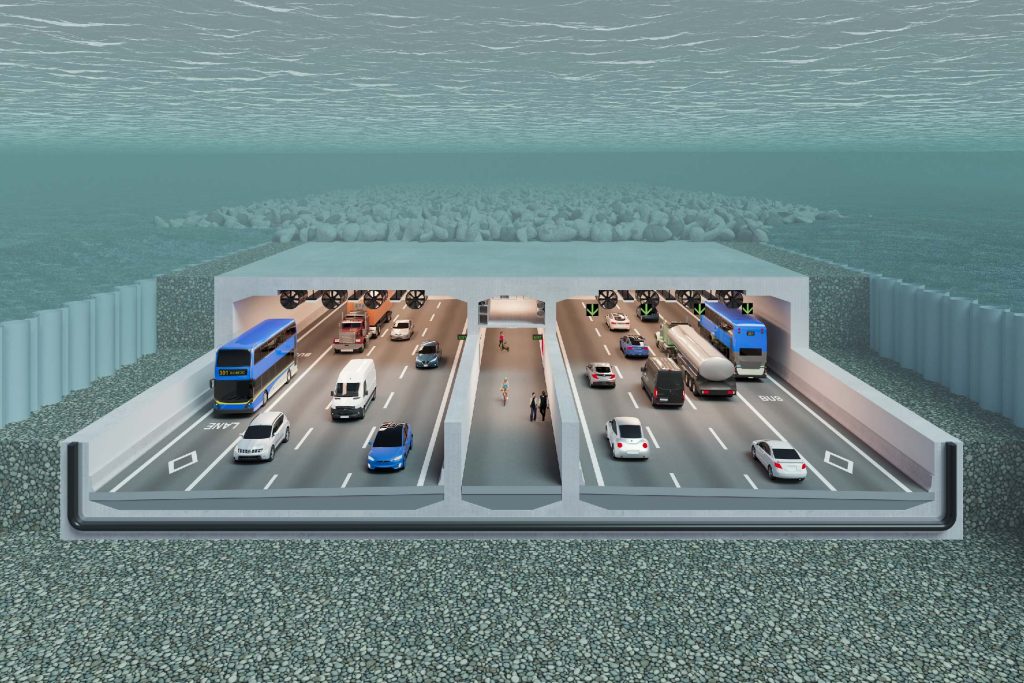

The Scale: The new tunnel will be made of six tunnel elements. Each element will weigh approximately 60,000 tonnes and will be 130 x 45 metres or about the size of a football field.

Step 1: The tunnel elements will be made on Deas Island to promote efficiency and reduce construction traffic in the region.

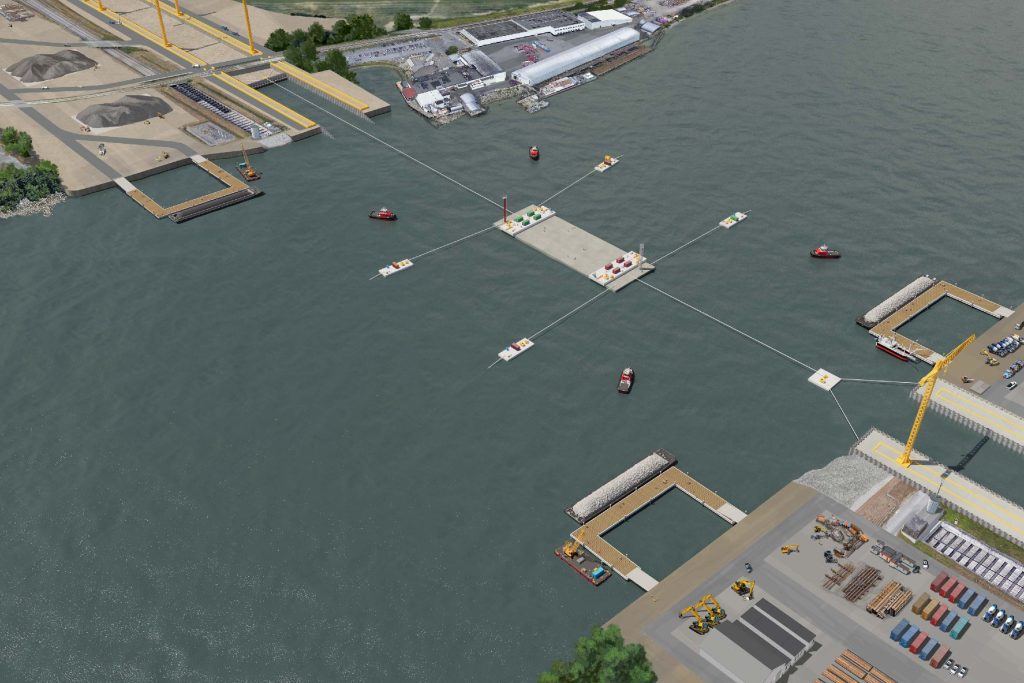

Step 2: The tunnel elements will be stored until the riverbed is ready for them, and when ready, tugboats will guide the element into position.

Step 3: Cables that span the river will secure the tunnel elements before they are carefully lowered into place. This process is called immersion.

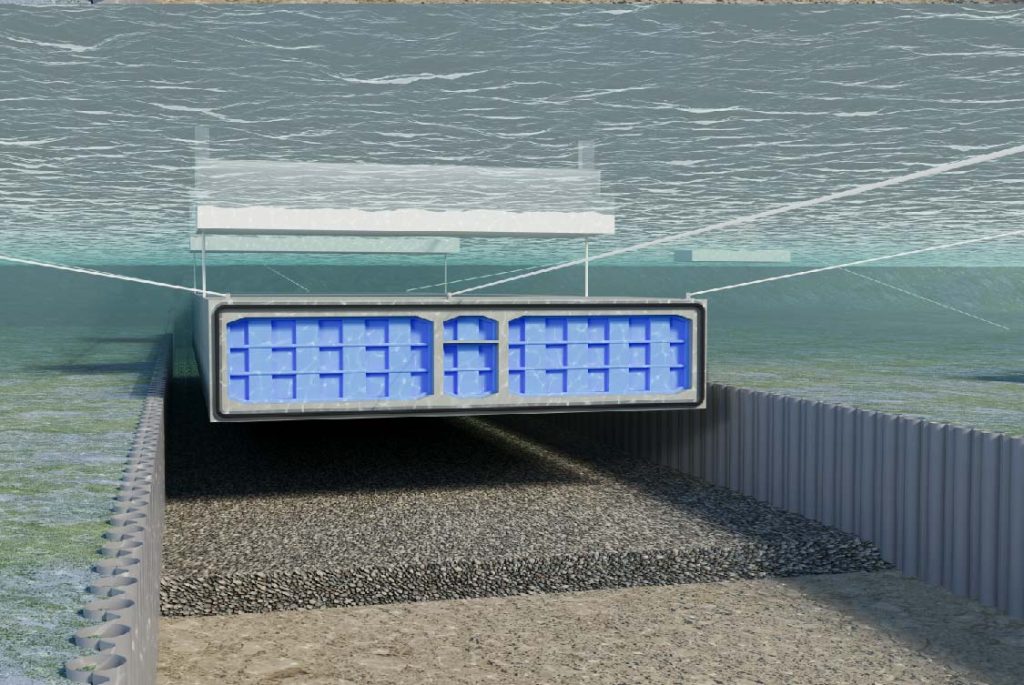

Step 4: While the tunnel elements are built, a machine dredges a trench at the bottom of the river. The trench is then prepared for an element to be lowered into place.

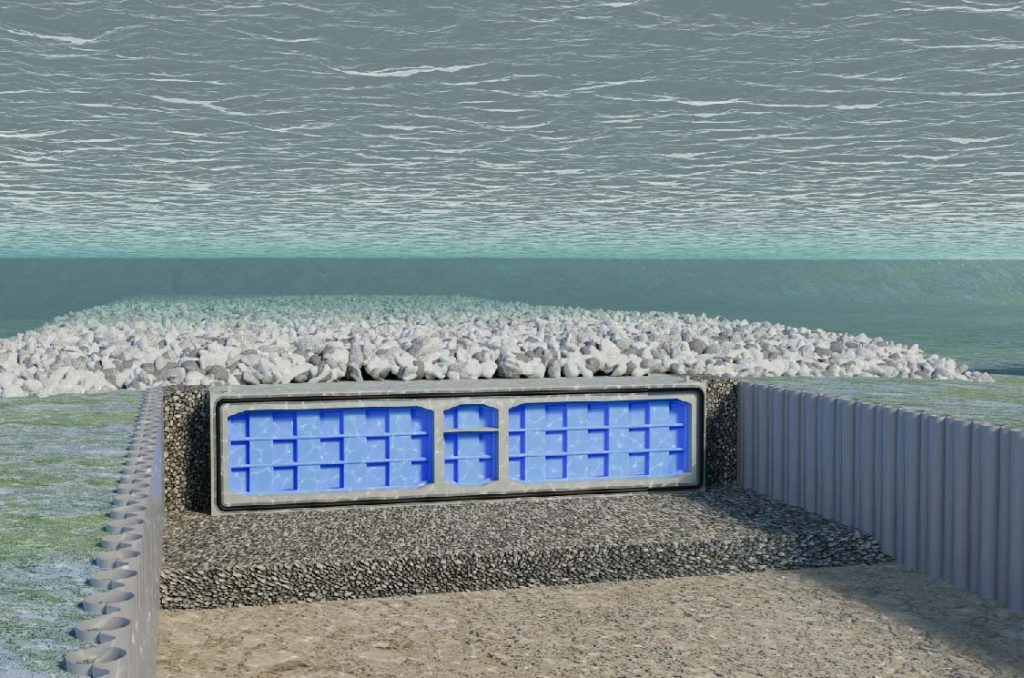

Step 5: Special tanks within the tunnel elements are filled with water to help lower the tunnel into position.

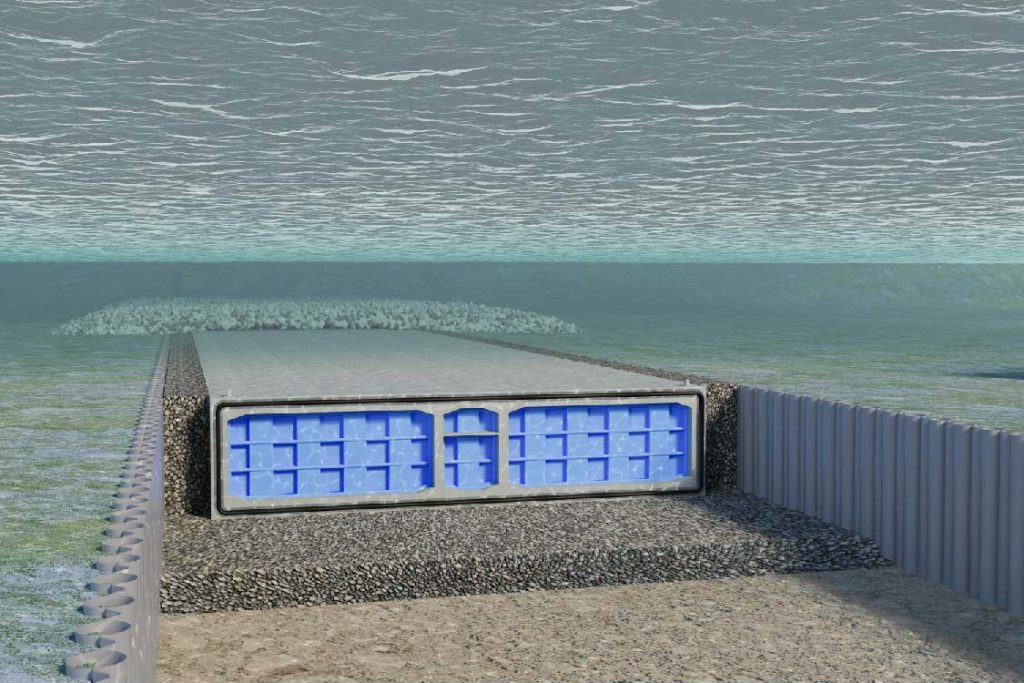

Step 6: Once the tunnel element is in place, gravel is added to the sides to secure it.

Step 7: Large boulders are placed on top of the tunnel elements to protect them in the future. The immersion process is repeated six times to lower each element.

Once completed the new tunnel will improve traffic flow and access for emergency vehicles. Dedicated bus lanes will make transit trips faster and more reliable. The tunnel will also include the option to walk or cycle at this crossing for the first time.